1/1/2000 AECHELON TECHNOLOGY AND AFRL’S WARFIGHTER TRAINING DIVISION DEMONSTRATE NVG SIMULATOR AT I/ITSEC ’99

Night Flying Revolution

Tim Ripley profiles the latest developments at the USAF’s research laboratory ( AFRL ) to simulate the use of night vision goggles by pilots.

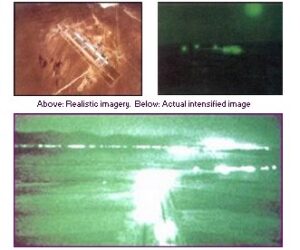

With night operations an increasingly critical part of military operations, the need to provide realistic simulation environments is taking on growing importance. Simulating night vision goggles (NVGs) has long been a major challenge, but one answer to this problem was on display at last December’s I/ITSEC show in Orlando.

In an F-16 simulator equipped with a full field-of-view visual display, resplendent in USAF Viper logos, military aviators, service simulation experts and industry professionals were able to see for themselves the novel approach taken by Colonel Bill Berkley, Dr Elizabeth Martin and the fly-by-night team from the night vision programme of the AFRL’s Warfighter Training Research Division.

“We do not use actual night vision goggles (NVG) because, in our view, all attempts to utilise visual displays to simulate actual goggles have not been a success” said Colonel Berkley. “It has not been possible to obtain realistic goggle or out-the-window images using that approach.”

“Instead, we use a helmet-mounted display for a simulation of the NVG image with special software to capture the NVG effects, that also permits us to produce fully correlated realistic out-the-window night scenes – that was an absolute requirement of the user” said Colonel Berkley. “In that respect this system is unique. No one in industry is working this way, we are on our own.”

Goggle experts

Colonel Berkley’s fly-by-night training team is at the centre of American efforts to meet operational training needs of aircrew using night vision devices, particularly NVGs. The team develops training manuals, conducts instructor training and provides technical support for operational units. “The official courseware we produce is used by the USAF, US Navy and Marine Corps for initial training, and to a lesser extent by the army.

“A basic driver of everything we do is a very strong primary operational requirement to develop a capability for night war fighting” he says. “Secondly there is a requirement for effective, affordable training for aircrews. Everyone involved recognised that the ability to fight at night is critical to success.

“The device we displayed at I/ITSEC is the focus of our programme and has the greatest resources committed to it. It is technically sophisticated and difficult.

“We believe that totally immersive training is the most effective – the analogy we like to use is that typical didactic training will inform the student but does not train the hairs on the back of his neck. Fully effective training for a task includes an intuitive sense of what works and what doesn’t, what is safe and what isn’t. To be successful we must immerse the student in the task, in an environment that is realistic.”

Night vision training system

Review and analysis of existing training systems identified a number of limitations inherent in existing NVG simulations that could not be overcome with the traditional simulation approach. The AFRL team therefore developed the night vision training system (NVTS) that has involved a complete simulation approach.

The goal of the NVTS programme is to produce high-fidelity, deployable, low-cost, NVG simulation that will enable mission training, preview and rehearsal, whenever and wherever necessary. NVTS is a research and development project that will continue development and transition to users.

“The cockpit device and visual device are products of another branch of the laboratory” says Colonel Berkley. Eventually the NVTS technology will be transitioned to a wide range of simulator platforms.

The NVG imagery is drawn from the modelling of unique two-dimensional NVG effects such as halos, gain response based on an accurate characterisation of goggle sensitivity, gain, resolution, colour and field of view. The imagery is presented through a head-tracked cathode ray tube (CRT) based display, mounted in an actual NVG shell. This approach allows for correct eyepoint for all crew members. Each display requires at least one channel of imagery.

The three-dimensional world incorporates high resolution material, classified imagery and accurate per-texel radiometric response of surface reflectance and aspect. A single database is used that completely correlates with visual and multiple sensor simulations, that will ultimately allow NVG, FLIR and radar imagery to be matched to out-the-window scene.

Features

A correlated photographic and material classified database covers 380 nautical miles by 420 nautical miles of the Nellis training range in Nevada. This database was derived from multi-spectral satellite imagery, aerial photography, material spectral response data and elevation data. This database includes inserts with sub-metre resolution imagery and full three-dimensional cultural feature extraction.

Each data base – the NVG, out-of-the-window and radar/sensor – are correlated and the pilot has a head tracker attached to his helmet. This ensures that the image seen in the NVG matches the other views.

The NVG sensor simulation uses a physics-based approach to provide an accurate in-band, radiometric response for reflectance and aspect of the material-coded texel under illumination. As illumination level and angle change in the simulation, the amount of light reflected from each texel to the view point changes in realtime.

“We used special measurements of goggles performance and characteristics to build up our NVG visual display database” he explains. “For example, we know precisely how halos created by different light sources appear in NVGs.”

High-resolution helmet-mounted displays (HMD) present the simulation to the user. These displays incorporate miniature CRTs mounted inside NVG shells, called the aatavisor, to provide the same form, fit and function of actual NVG, with the same weight and centre of gravity as the NVGs being modelled. The CRTs replace the imaging tubes in real NVGs, allowing them to be driven directly by a computer or camera video source. It uses the same phospher as current NVGs in order to provide the same colour and decay characteristics. The current HMDs used have a display resolution up to 1700 pixels by 1350 lines, non-interlaced, refreshing at 60Hz.

Partners

“The basic concept of operation of our laboratory is to collaborate with those individuals and colleagues who wish to jointly develop ideas” said Colonel Berkley. “We assist them by sharing resources and expertise to pursue joint objectives.”

“One of the important things to emphasise about the NVTS is the partners in the development who made important and substantial contributions – our three on-site contractors, Boeing, Raytheon and Lockheed Martin” adds Berkley. “For this project we teamed up with Silicon Graphics who provided Onyx 2 image generator, n-vision inc who provided the NVG device and Aechelon Technology who carried out database modelling development and assisted with inserting the goggle effects. Datacube, SGB Enterprises, Photon Research Associates and Surface Data were also collaborators. The USAF, Navy and Marine Corps and Naval Air Warfare Centre Training systems division provided military input.”

The future

“The next stages in the programme will be to further develop the goggle characteristics for NVG imagery, as well as the development of additional databases, with various terrain and cultural features” he said. “Combat effects, various weather and environmental effects such as seasonal changes will be incorporated in the near future. We plan to do training effectiveness studies, to determine specific tasks that can be trained and for what applications this device will be best suited.

“The system has been selected by USMC for use in its future simulator acquisition programmes and for another USAF aircraft [simulator programme]. It could be in operational use in as little as one and a half years.

“Industry is showing a lot of interest in NVTS” confirms Colonel Berkley. “It is acknowledged as a more successful approach and is also being enthusiastically embraced by representatives of US military services as a system they would like to employ.”